Ever stared at a spec sheet for a smartphone camera lens or a tiny surgical drill bit and wondered just how small 3.9 mm really is? It’s one of those measurements that sits right on the edge of "barely visible" and "precision engineering." If you’re trying to visualize 3.9 mm to in, you’re looking at approximately 0.15354 inches.

That is thin.

Think about the thickness of two nickels stacked on top of each other. You're getting close. It’s small enough that a tiny error in conversion can ruin a 3D print or make a mechanical watch gear fail. Most people just round it to 0.15 inches and call it a day, but in fields like medical tech or high-end electronics, those extra decimal places are the difference between a perfect fit and a total disaster.

The Math Behind 3.9 mm to in

Converting metric to imperial isn't just about moving a decimal point. It’s a hard ratio. Since 1959, the international inch has been defined as exactly 25.4 millimeters. This wasn't always the case—back in the day, the US and the UK had slightly different ideas of how long an inch was, which was a nightmare for global manufacturing.

To get your answer, you take 3.9 and divide it by 25.4.

$$3.9 / 25.4 = 0.1535433070866...$$

✨ Don't miss: How to Turn Word into Light Mode When Your Eyes Are Tired of the Dark

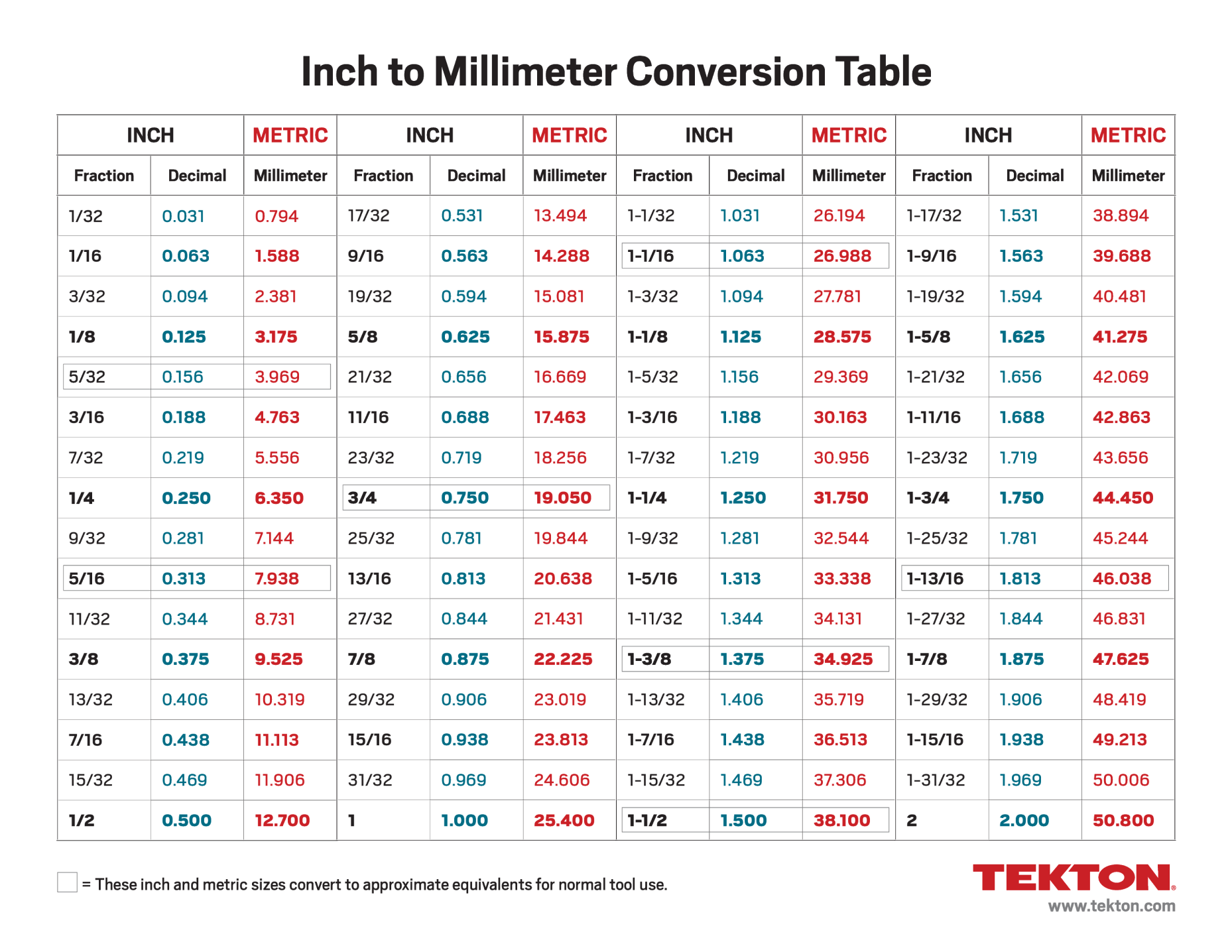

Honestly, nobody needs that many numbers. For most DIY projects or general visualization, 0.15 inches or the fraction 5/32 of an inch (which is about 0.156) gets the job done. But if you are a machinist working with a CNC router, you’re going to be looking at that 0.1535 mark very closely.

Why do we still use both?

It's a mess, isn't it? The US, Liberia, and Myanmar are the lonely holdouts on the imperial system. Meanwhile, the rest of the scientific world runs on base-10. This creates a weird friction where a designer in Germany develops a 3.9 mm component, and a technician in Ohio has to figure out which drill bit to grab.

Where You’ll Actually Encounter 3.9 mm

You might think 3.9 mm is an obscure number, but it pops up in some surprisingly high-stakes places.

Medical Endoscopy

In the world of ENT (Ear, Nose, and Throat) medicine, the diameter of an endoscope is everything. A 3.9 mm pediatric bronchoscope is a standard size. Why? Because it’s small enough to navigate the narrow airways of a child without causing trauma, yet just large enough to house high-definition fiber optics and a working channel for tiny surgical tools. If that scope was even half a millimeter wider, it might not fit. If it was thinner, the image quality would tank.

Smartphone Tech

Look at the camera "bump" on the back of your phone. The focal length of these tiny lenses often hovers around the 4 mm mark. A lens with a 3.9 mm focal length is common in wide-angle mobile photography. It’s the sweet spot for capturing a landscape without creating that weird "fisheye" distortion at the edges of the frame.

Mechanical Engineering and Fasteners

In the world of screws and bolts, you’ll often find M4 fasteners. While a true M4 screw has a 4 mm major diameter, the actual "tap drill" size—the hole you drill before cutting the threads—is often close to 3.9 mm for certain fit classes. If you grab a 5/32 inch drill bit (0.156 in), you’re actually drilling a hole that is roughly 3.96 mm.

Is that 0.06 mm difference a big deal?

In wood? No. In aerospace-grade aluminum? Absolutely. It’s the difference between a screw that holds under pressure and one that strips the threads and sends a component flying.

Fractions vs. Decimals: The 5/32 Trap

If you’re in a hardware store looking for something that matches 3.9 mm to in, you won't find a box labeled "0.1535 inches." You’ll find fractions.

The closest common fraction is 5/32".

But here is the catch: 5/32" is actually 3.9688 mm. If you’re trying to fit a 3.9 mm rod into a 5/32" hole, you’ll have about 0.07 mm of "play" or wiggle room. For a door hinge, that's fine. For a high-speed cooling fan bearing, that wobble will eventually destroy the motor.

Always know your tolerances. "Close enough" is a dangerous phrase in engineering.

🔗 Read more: Turning on Wifi Calling iPhone: Why Your Bars Don’t Actually Matter Anymore

The Mental Shortcut for Metric Conversions

If you don't have a calculator handy, here is how I usually do it in my head. I know that 1 mm is roughly 0.04 inches (it's actually 0.0393, but 0.04 is easier).

So, for 3.9 mm:

4 mm x 0.04 = 0.16 inches.

Then just shave a tiny bit off that estimate.

You end up at 0.15. It’s a quick and dirty way to realize that 3.9 mm is a bit more than an eighth of an inch (0.125) but less than a quarter inch (0.25).

Real-World Precision: A Lesson from History

Precision matters. Take the Mars Climate Orbiter disaster of 1999. One team used metric units (newtons), while another used imperial units (pound-force). The spacecraft got too close to the Martian atmosphere and disintegrated.

That wasn't a 3.9 mm error—it was much larger—but it illustrates the fundamental danger of "assuming" conversions. When you’re dealing with 3.9 mm to in, especially in 3D printing or CAD design, always set your software to one unit and stick to it. Don't convert back and forth mid-project. Every time you convert and round a decimal, you introduce a "rounding error." Do that five times, and your final part won't fit the assembly.

How to measure 3.9 mm accurately

If you’re trying to verify a part is actually 3.9 mm, put the wooden ruler away.

Standard rulers have markings for millimeters, but human error when looking at those tiny lines is huge. Parallax error—where the angle of your eye changes the reading—can easily swing your measurement by 0.5 mm.

Use a digital caliper.

A decent pair of Mitutoyo or even a mid-range Neiko caliper will let you toggle between mm and inches with a single button. This eliminates the math entirely. When you close the jaws on a 3.9 mm object, you can see 0.1535 in appear instantly. It’s the only way to be sure when you’re working at this scale.

Common Objects that are roughly 3.9 mm:

- The diameter of a #6-32 machine screw.

- A standard 4-gauge electrical wire (actually 4.1 mm, but close).

- The thickness of a high-end leather belt.

- The width of a heavy-duty zip tie.

Precise Tooling Steps

If you are working on a project requiring this specific dimension, here is how you should handle it:

- Identify the Tolerance: Does the part need to be exactly 3.9 mm? If you have a +/- 0.1 mm tolerance, you can use a 5/32" drill bit. If you have a +/- 0.01 mm tolerance, you need a metric-specific cobalt drill bit.

- Set Your Calipers: Always zero your calipers before measuring.

- Use the "Divide by 25.4" Rule: Don't trust charts that round too early. Do the math yourself to at least four decimal places.

- Check for Thermal Expansion: If you’re measuring metal in a hot garage versus a cold basement, that 3.9 mm can actually change. Steel expands about 0.000012 meters per meter per degree Celsius. At 3.9 mm, it’s negligible for a birdhouse, but vital for an engine block.

Understanding the transition from 3.9 mm to in is really about understanding the scale of the world we can't easily see. It’s the world of internal electronics, precision medical devices, and the fine threads of the bolts that hold your laptop together. Respect the decimal, and your projects will actually fit together the first time.

Actionable Next Steps

If you are currently designing a part or searching for a tool, stop and check your required precision. For a loose fit, use a 5/32" drill bit or a 0.15" setting. However, if you are working with press-fit components or 3D printer nozzles, ensure your software is set to Metric to avoid the rounding errors inherent in the 25.4 conversion factor. If you frequently work between these two systems, invest in a machinist's conversion chart that lists "decimal equivalents" to avoid doing the math under pressure.