You’re staring at a piece of pipe. You’ve got your tape measure out. You hook it onto the inner edge, pull it across the center, and read the mark. One inch. Perfect. You go to the hardware store, grab a one-inch fitting, head home, and... it doesn't fit. Not even close.

Honestly, it’s maddening.

The world of plumbing and industrial piping is built on a legacy system that feels like it was designed to confuse anyone without a master's degree in mechanical engineering. When people go looking for a pipe size chart ID, they’re usually trying to solve a very specific problem: "What is the actual hole in the middle of this tube?" But in the industry, "Internal Diameter" or ID is a moving target. It’s not a fixed number you can just guess. It’s a dance between the Nominal Pipe Size (NPS) and the wall thickness, which we call "Schedule."

If you don’t get the ID right, your flow rates are trashed. Your pressure drops. Your pumps burn out. It's a mess.

📖 Related: Why Different Emojis on Different Phones Keep Ruining Your Group Chats

The NPS Lie and How it Affects Your Pipe Size Chart ID

Here is the weird truth: for any pipe size under 14 inches, the name of the pipe has almost nothing to do with its physical dimensions. If you buy a 2-inch pipe, neither the outside nor the inside is actually 2 inches.

Why? History.

Back in the day, pipes were made with thick walls. As manufacturing got better, we figured out how to make walls thinner while keeping the same strength. But instead of changing the outside diameter—which would have made every existing fitting in the world useless—engineers kept the Outside Diameter (OD) constant and expanded the Internal Diameter.

This means that on a standard pipe size chart ID, the ID changes based on how "heavy" or "thick" the pipe is. A Schedule 40 pipe (the standard stuff you see at Home Depot) has a different ID than a Schedule 80 pipe (the heavy-duty stuff), even if they are both "2-inch" pipes.

If you are looking at a 1/2-inch NPS pipe:

The OD is always 0.840 inches.

If it’s Schedule 40, the ID is 0.622 inches.

If it’s Schedule 80, the ID shrinks to 0.546 inches because the walls are thicker.

See the problem? If you’re calculating flow for a hydraulic system and you assume the ID is 0.5 inches because it’s a "half-inch pipe," your math is going to be wrong by over 20%.

Why Schedule Matters More Than You Think

People often ask me if they can just swap Schedule 40 for Schedule 80. Sure, if you want to spend more money for a smaller hole. Schedule 80 is rated for higher pressure, but because that extra strength comes from thicker walls protruding inward, your pipe size chart ID gets smaller.

This is a classic trap in DIY irrigation or home workshops. You think "stronger is better," so you buy the thick-walled pipe, but now your water pressure is lower because you’ve constricted the path.

Cracking the Code: The Actual ID Numbers

Let’s look at some real-world figures. You don't need a PhD, but you do need to stop trusting the label on the bin.

For a 1-inch nominal pipe, the OD is 1.315 inches.

- In Schedule 40, the ID is 1.049 inches.

- In Schedule 160 (ultra-thick), the ID drops to 0.815 inches.

Think about that. A "1-inch" pipe can have an internal opening ranging from over an inch to barely 13/16ths of an inch. That’s a massive delta.

When you get above 14 inches, the industry finally stops playing games. For pipes 14 inches and larger, the NPS is the OD. So a 14-inch pipe is exactly 14 inches on the outside. But even then, the pipe size chart ID is still a variable based on the wall thickness. You still have to do the subtraction.

Copper vs. PVC vs. Steel: The Great ID Confusion

If you’re moving from steel to copper, throw everything you just read out the window. Copper doesn’t use NPS. It uses CTS (Copper Tube Size).

In copper piping, the Nominal Size is generally closer to the OD. For Type L or Type M copper—the stuff in your walls—the ID is almost never what you think it is. Type K has the thickest walls, Type L is medium, and Type M is thin. Because the OD is fixed so they all fit the same solder joints, the pipe size chart ID for copper fluctuates just as wildly as steel.

Steel pipe ID calculations are governed by standards like ASME B36.10M. If you’re working in a refinery or a high-pressure gas environment, you don't guess. You check the mill test report. For the rest of us, we rely on a standardized pipe size chart ID to make sure our flow velocity stays under 5 feet per second to prevent erosion.

Calculating the ID Yourself

If you don't have a chart handy, you can find the ID with a simple bit of math. You need the Outside Diameter and the Wall Thickness.

✨ Don't miss: Watching Life Breathe: Why the Plant Cell Under Microscope Looks Nothing Like Your Textbook

The formula is $ID = OD - (2 \times Wall Thickness)$.

You have to multiply the wall thickness by two because the wall exists on both sides of the circle. I've seen professional contractors forget this and end up with parts that don't fit. It's an easy mistake to make when you're tired and covered in PVC primer.

The Impact of Internal Diameter on Flow Velocity

The ID isn't just a trivia point. It's the engine of your fluid system. The cross-sectional area of the pipe is calculated using the ID ($Area = \pi \times r^2$).

Even a tiny change in the pipe size chart ID results in a huge change in area.

A 1-inch Schedule 40 pipe has an ID of 1.049.

A 1-inch Schedule 80 pipe has an ID of 0.957.

That’s less than a 10% difference in diameter, but it results in a nearly 17% reduction in flow area.

If you are trying to move a specific volume of liquid, that 17% loss means your pump has to work significantly harder, generating heat and wasting electricity. Honestly, this is where most "engineered" systems fail—someone swapped the pipe spec without updating the pump calculations.

Finding the Right Pipe Size Chart ID for Your Project

So, how do you actually use this information?

- Identify your material. Is it PVC, Black Iron, Stainless Steel, or Copper? Each has its own standard.

- Determine the Schedule. Look for the printing on the side of the pipe. It’s almost always there.

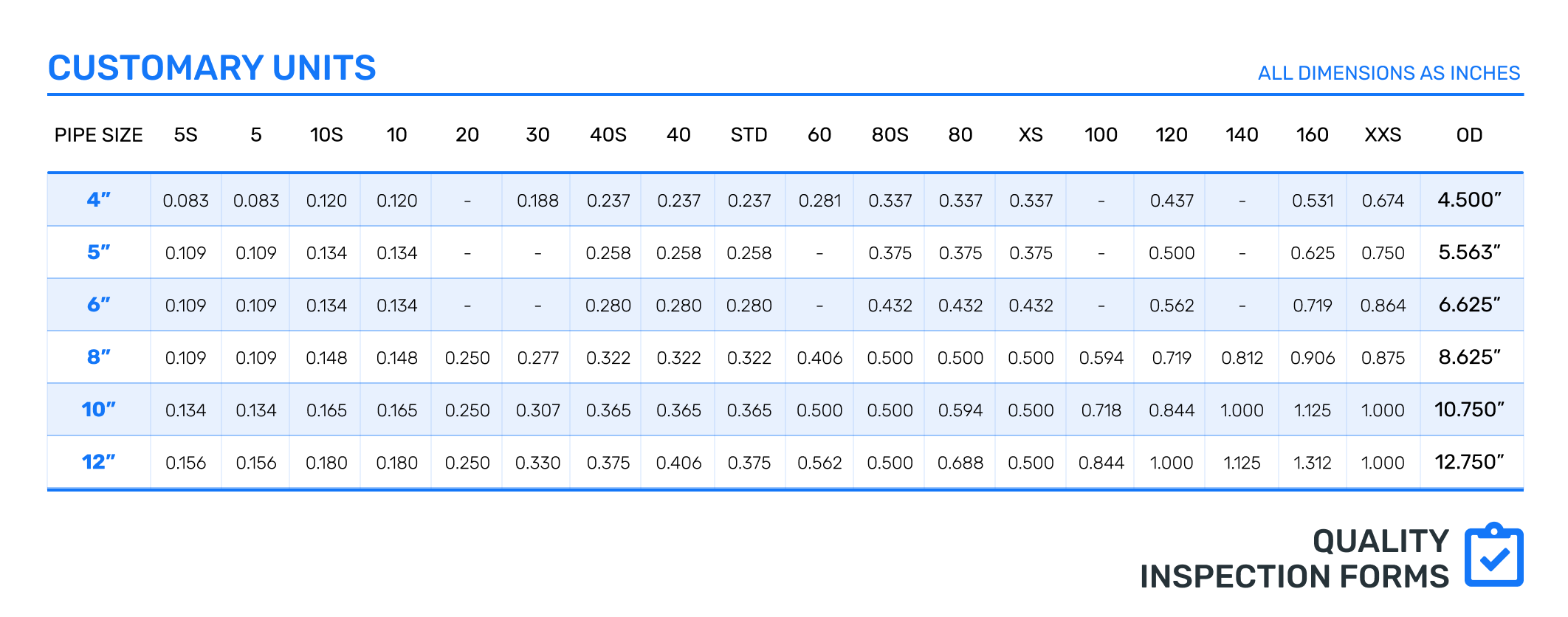

- Use a verified chart. Don't trust a random image on a forum. Look for charts that reference ASME (American Society of Mechanical Engineers) or ASTM (American Society for Testing and Materials) standards.

- Measure with Calipers. If the pipe is old and the markings are gone, use a digital caliper to get the OD. Once you have the OD, you can cross-reference it with a chart to find the likely NPS and Schedule, which then gives you the ID.

Real-World Examples of ID Failures

I once saw a brewery installation where they used Schedule 80 PVC for everything because they wanted "the best." They calculated their flow rates based on Schedule 40 pipe size chart ID values. When they turned the system on, the friction loss was so high that the beer was foaming at every tap. They had effectively throttled their own business because they didn't realize that "higher schedule" meant "smaller hole."

Another common one is exhaust systems. People buy tubing based on OD, but turbochargers care about ID. If you buy 3-inch tubing with a 1/8-inch wall, your ID is 2.75 inches. That’s a lot of lost air.

Actionable Steps for Accurate Measurement

Stop guessing.

First, get yourself a decent pair of digital calipers. They’re cheap now, and they’ll save you three trips to the hardware store.

Second, always ask for the "Schedule" when buying pipe. If the salesperson says "it's just standard," they mean Schedule 40.

Third, before you buy any fittings, especially for high-pressure or critical flow applications, check a physical pipe size chart ID table. Verify the decimal inches.

Finally, remember that "Nominal" means "in name only." It is a label, not a measurement. Treat it like a nickname. You wouldn't use a nickname to fill out a legal document; don't use a nominal size to build a pressurized system.

Grab a copy of the ASME B36.10M dimensions if you're working with steel. If you’re working with plastic, look at ASTM D1785. Keep these charts bookmarked or printed in your shop. When in doubt, measure twice—not the outside, but the wall—and do the math. Your pumps, your pipes, and your sanity will thank you.