If you walk into a massive pharmaceutical plant in New Jersey or a supplement giant in Utah, you’ll see rotary presses. These beasts are the Ferraris of the industry, spitting out a million tablets an hour while making a deafening mechanical roar. But tucked away in the R&D labs, or the backrooms of boutique herbalists, you’ll almost always find a single punch tablet press. It’s small. It’s relatively quiet. It’s also the most important piece of equipment in the building.

Why? Because you can't just throw a bucket of powder into a high-speed machine and hope for the best.

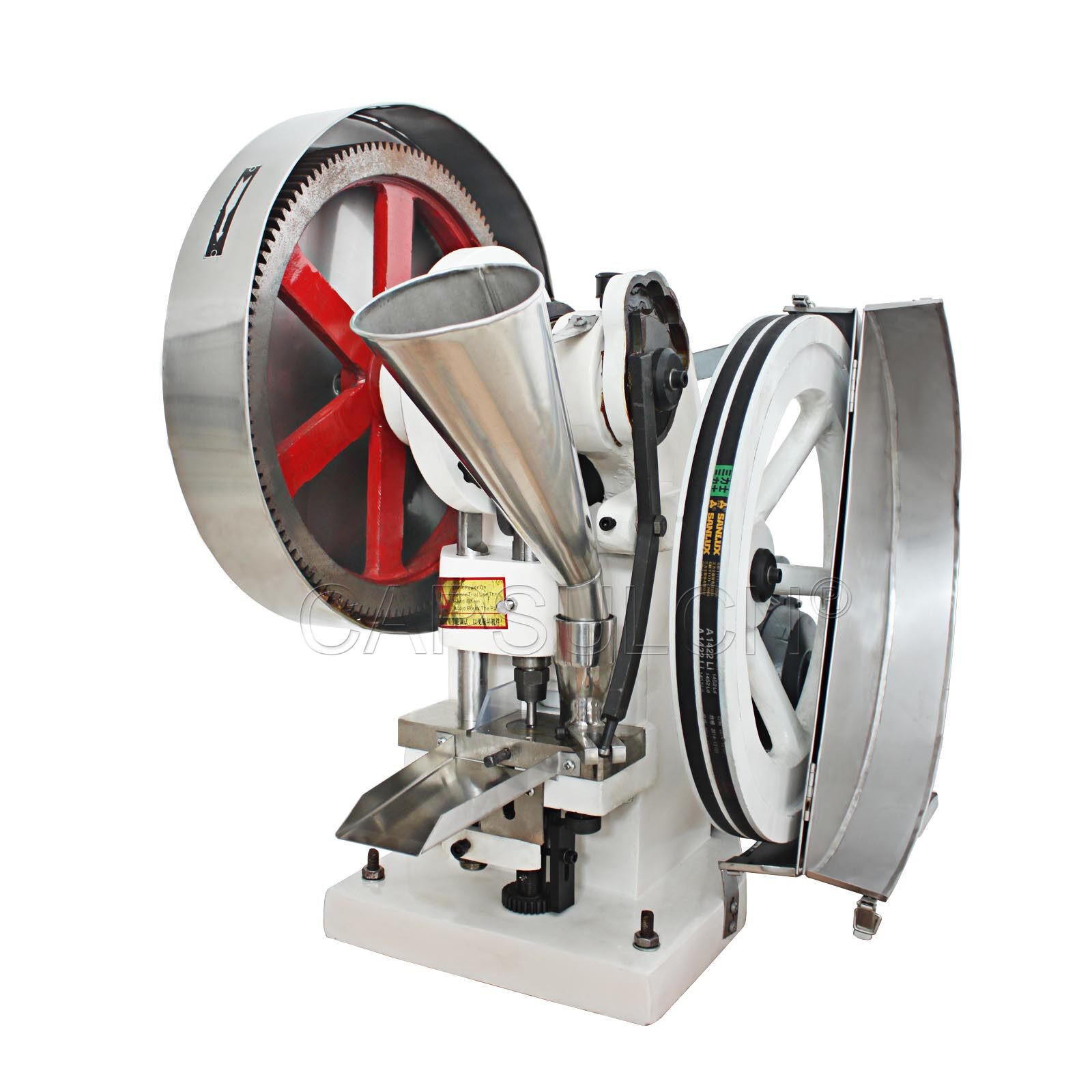

A single punch tablet press, often called an eccentric press or a lab-scale press, is basically the "first draft" of the drug world. It uses a single set of station tooling—one upper punch, one lower punch, and a die. You feed it a bit of powder, the cam swings, and clack—you have a pill. It’s simple. It’s tactile. Honestly, it’s the only way to figure out if your formula is actually going to work before you waste fifty grand on a production run that crumbles into dust.

How a Single Punch Tablet Press Actually Works (Without the Fluff)

Most people think these machines just "squish" things. Well, they do. But the physics of it is actually kinda cool. In a standard eccentric machine, like the classic TDP-5 models you see everywhere, the bottom punch stays still during the actual compression. The top punch does all the heavy lifting. It’s a vertical hammer strike, basically.

The process follows a rhythm. First, the "filling" stage. The hopper drops powder into the die cavity. Then comes the "compression." The upper punch descends, hitting the powder with several kilonewtons of force. Finally, the "ejection." The lower punch rises up to flush the new tablet out of the die so it can slide down the chute.

Why the Eccentric Design Matters

Unlike rotary presses that use a track system to nudge punches up and down, the single punch relies on a large, heavy cam or an eccentric wheel. This is why these machines are so heavy for their size. A desktop unit might weigh 150 pounds because it needs that raw mass to keep the vibration from shaking the bolts loose. If you’ve ever used a manual TDP-0, you know the feeling of cranking that wheel by hand. It gives you a physical "read" on the compressibility of the material that a digital readout just can't match.

The Reality of R&D and Small Batches

Let's get real about the use cases. If you're trying to launch a new Vitamin C supplement, you aren't starting with a 36-station rotary. You're starting here.

I’ve seen labs spend weeks just trying to get the "flow" right. See, powder is finicky. If it’s too dry, the tablet caps—meaning the top layer pops off like a lid. If it’s too oily, it sticks to the punch face. On a single punch tablet press, you can test five different versions of a formula in an afternoon. You change the depth of the fill, swap the punch for one with a different logo, and try again. It's the ultimate prototyping tool.

- Clinical Trials: When a biotech firm is in Phase I trials, they might only need 500 tablets. Setting up a massive industrial machine for that is a nightmare. It takes longer to clean the big machine than it does to run the batch.

- Education: Pharmacy schools love these. You can actually see the mechanical parts moving. It’s "Tableting 101" in a box.

- Niche Manufacturing: Think of things like aquarium fertilizer tabs, ceramic pellets, or even those little "magic" expanding towels.

The Problems Nobody Mentions in the Brochure

Sales reps love to tell you how easy these machines are. They aren't always easy. In fact, single punch presses have a reputation for being "loud and clunky" if they aren't timed perfectly.

One big issue is "lamination." Because the compression happens from the top only in many models, the density of the tablet isn't always uniform. The top might be rock-hard while the bottom is soft. Modern engineers like those at Natoli Engineering or Ivoclar have spent decades researching how to fix this, but the physics of a single-direction strike is what it is.

Another thing? Dust. These machines aren't always fully enclosed. If you're working with anything remotely "active" or dusty, you’re going to need a vacuum system or a localized HEPA filter. Don't think you can just set this up on a kitchen table and not end up with fine white powder over every single surface in the room. You've been warned.

Maintenance: The "Hidden" Job

If you own a single punch tablet press, you are now a part-time mechanic. You’ll need to get comfortable with food-grade grease.

The most common failure point isn't the motor; it’s the tooling. If you don't clean the punches after every use, the residue hardens. Then, the next time you run it, the punch gets stuck in the die. This can actually snap the timing belt or even bend the main drive shaft on cheaper import models. Use an ultrasonic cleaner for the punches. It's worth the $80. Also, keep an eye on the "ejection height." If the lower punch doesn't come up exactly flush with the die table, your tablets will get clipped and come out looking like bitten crackers.

✨ Don't miss: Where Can You Pay Spectrum Bill: All the Fast Ways to Settle Up

Comparing the Big Players

If you're looking to buy, you're usually looking at three tiers.

At the bottom, you have the entry-level TDP series (TDP-0, TDP-1.5, TDP-5). These are the workhorses of the world. They are cheap, parts are everywhere, and they are easy to fix. But they are also messy and lack the precision sensors needed for high-end pharma.

In the middle, you have companies like LFA Machines. They’ve taken those basic designs and upgraded the safety features, adding things like sensors and better guards. This is where most small-to-medium businesses live.

At the top end, you have brands like Korsch or Fette. These aren't just presses; they are data-logging computers that happen to make tablets. They measure the "ejection force" and "pre-compression" in real-time. If you're a scientist at Pfizer or GSK, this is what you’re using. They can cost as much as a luxury SUV, but they give you the data needed to scale up to a million tablets a day later on.

What Most People Get Wrong About Tooling

"Tooling" refers to the punch and die set. People think you can just buy any punch and stick it in any machine. Nope.

You have "B" tooling and "D" tooling, which are international standards (TSM or EU standards). Most single punch machines use their own proprietary sets, though. If you want a custom shape—say, a tablet shaped like a star or a bone—you have to get it custom-milled. This usually takes 4-6 weeks. Don't expect to order a custom logo and have it by Friday.

Also, the "fill depth" isn't just about weight. It's about volume. If your powder is fluffy, you need a deeper die. If it’s dense like sand, you need a shallow one. You’ll spend half your time adjusting the "lower timing" to get the weight consistent within a 1% margin.

Safety Is Not Optional

I’ve seen some old-school guys bypass the plastic guards because they want to "see the action." That is a terrible idea. These machines use tons of pressure. If a punch shatters because it hit a stray bolt, it doesn't just crack; it turns into shrapnel.

Always check your "overload protection." Most modern machines have a shear pin or a spring-loaded mechanism that gives way if the pressure gets too high. If you're using an older machine without these, you are essentially operating a small, slow-motion bomb. Wear your safety glasses. Keep your fingers away from the "shoe" (the part that slides the powder).

How to Get the Most Out of Your Press

- Granulate your powder: Don't just mix powders and hope. Use a binder like Microcrystalline Cellulose (MCC). It makes everything stick together and flow better.

- Lubricate the mix: Add about 0.5% Magnesium Stearate. It prevents the tablets from sticking to the punches. Without it, you’ll have a jammed machine in ten minutes.

- Level the machine: If the press is slightly tilted, the powder won't fill the die evenly. Your weights will be all over the place.

- Listen to the sound: A healthy press has a rhythmic, metallic "thump." If you hear a "scrape" or a "ping," stop immediately.

Actionable Next Steps for New Users

If you're serious about getting into tableting, don't just buy the first machine you see on an auction site.

Start by calculating your required output. If you need more than 5,000 tablets a day, a single punch press will drive you crazy with the labor involved. You'd be better off with a small rotary. But if you’re doing R&D or small-run specialty items, the single punch is your best friend.

Check the availability of parts for the specific model you choose. Brands like LFA have great support videos online, which is a lifesaver when you're trying to figure out why your belt is slipping at 2:00 AM.

Lastly, invest in a high-quality scale that goes down to 0.001 grams. You cannot calibrate a tablet press with a kitchen scale. You need to know exactly how much each pill weighs to ensure your active ingredients are dosed correctly. Precision is the difference between a supplement that works and one that’s just a placebo.

The single punch tablet press might seem like a relic from a simpler era of manufacturing, but its versatility and ease of use keep it relevant. Whether you're a chemist at a multi-billion dollar lab or a hobbyist making custom fish food, this machine is the bridge between a pile of powder and a finished product. Respect the mechanics, keep it greased, and it’ll last you thirty years.