You've been there. It’s a humid Tuesday afternoon, and you're staring at a flatbed trailer that refuses to cooperate. The owner swears it worked yesterday. But right now? Nothing. No blinkers, no brake lights, just a dim, flickering ghost of a tail light that mocks your every move. You start crawling under the chassis with a multimeter, tracing wires through layers of road grime and electrical tape, praying the issue isn't buried inside the harness. It’s a massive time-sink. Honestly, diagnosing trailer wiring shouldn't feel like performing surgery in the dark.

This is where a trailer light test box becomes the most underrated tool in your arsenal.

Most people think they can just use their truck to test a trailer. Big mistake. Using a vehicle as your power source introduces too many variables. Is the fuse blown in the truck? Is the factory tow package acting up? By using a dedicated tester, you isolate the trailer completely. You become the power source. It’s about narrowing down the search area until there’s nowhere for the problem to hide.

The Reality of Why Trailer Wiring Fails

Trailer wiring is, frankly, a disaster by design. Most manufacturers use "vampire" clips or cheap butt connectors that corrode the second they see a hint of road salt. Because trailers sit idle for months, the copper inside the wires oxidizes. You get "green crusties" that kill continuity.

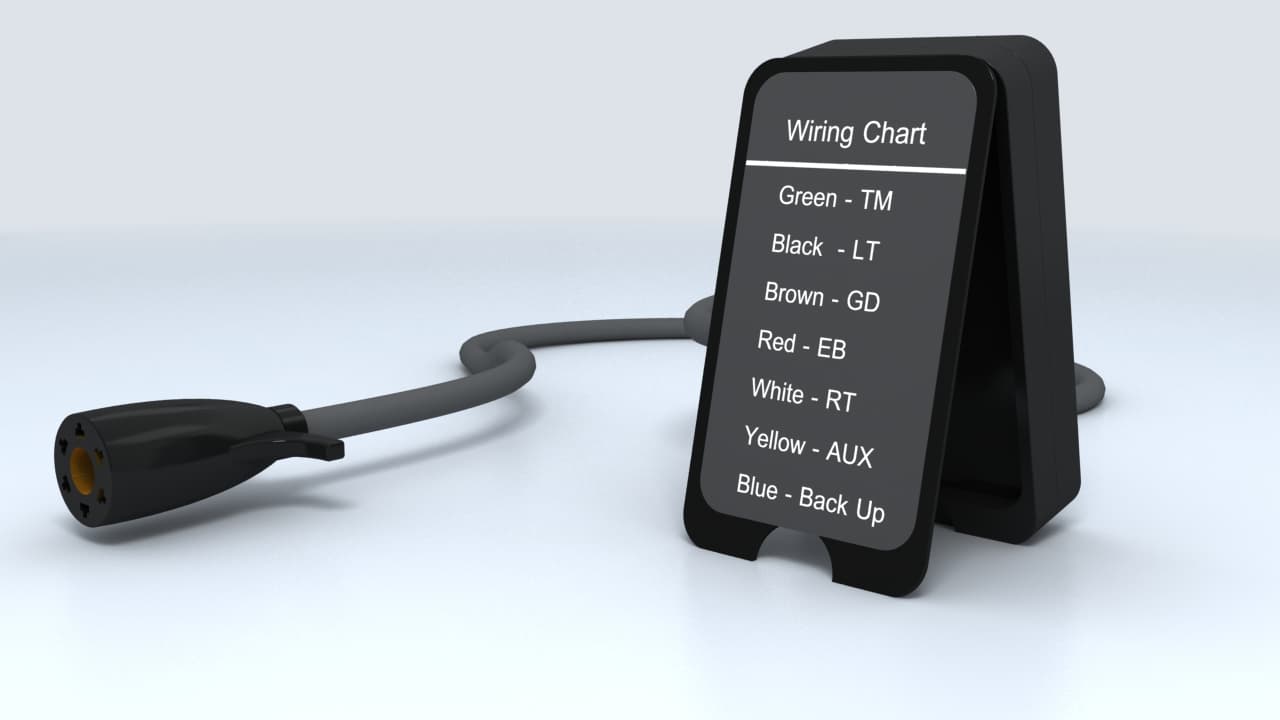

A trailer light test box bypasses the vehicle-side confusion. If you plug that box into the 7-way round or 4-way flat connector and the lights don't fire up, you know for a fact the issue is on the trailer. No guessing. No "maybe it's my pickup's relay." It provides a clean, 12V DC signal directly to the pins.

Professional vs. DIY Testers

You’ll see two main camps here. You’ve got the high-end units like those from IPA (Innovative Products of America), specifically their "Mutts" (Mobile Universal Trailer Testers). These things are beasts. They often come with internal batteries and remote controls so you can stand at the back of a 53-foot reef trailer and toggle the blinkers yourself. They are expensive, often ranging from $400 to over $1,000 for pro-grade fleet models.

Then you have the DIY route. A lot of guys just build their own using a plastic ammo can, a small sealed lead-acid battery, and a handful of toggle switches. It’s basically a battery-in-a-box. While it lacks the short-circuit protection of a pro unit, it gets the job done for a fraction of the cost.

What a Good Tester Actually Does

It’s not just about turning lights on. A solid trailer light test box acts as a diagnostic hub.

- Circuit Isolation: You can flip a switch for "Left Turn" and only that circuit gets juice. If the right side starts glowing too, you've got a short between circuits.

- Amperage Monitoring: Better units have an ammeter. If a single LED marker light is pulling 10 amps, you have a dead short to the frame.

- Electric Brake Testing: This is the big one. Testing electric trailer brakes without a vehicle is tough. A test box can send a signal to the magnets. You can actually hear them click or use a compass to see if they're generating a magnetic field.

- Ground Verification: Most trailer issues are ground issues. Period. A tester helps you verify if the white wire is actually doing its job or if the lights are trying to ground through the hitch ball.

The Troubleshooting Workflow That Saves Hours

Stop jumping around. If you're using a trailer light test box, follow a linear path. Start with the ground. Connect your tester and turn on the running lights. If nothing happens, check your ground pin. If the lights are dim, it’s a bad ground.

Next, hit the auxiliary power. If the trailer has an on-board battery (like a dump trailer or a camper), the tester should be able to check if that battery is receiving a charge.

Then move to the turn signals. This is where you find the crossed wires. It’s incredibly common for someone to swap the green and yellow wires during a "home repair." With the box, you’ll see the wrong light blink instantly. You don't have to keep running back to the cab of the truck to hit the signal stalk.

💡 You might also like: Did SpaceX Get the Astronauts Back: What Really Happened with the Starliner Crew

Common Misconceptions

People think a simple "plug-in" LED tester—those little $10 pucks you see at auto parts stores—is the same thing. It isn't. Those pucks test the vehicle, not the trailer. They tell you if your truck is sending a signal. They do absolutely nothing to help you find a broken wire on the trailer side. To test the trailer, you need a box that generates power, not just one that reads it.

Also, don't assume LEDs don't fail. While they last longer than incandescent bulbs, the control boards inside cheap LED fixtures hate moisture. A test box will often show a "flicker" on an LED circuit that a standard multimeter might miss because the box provides a consistent load.

The "Green Crusty" Problem

Corrosion is the enemy of all things electrical. When you're using your trailer light test box, pay attention to the brightness. If the lights look weak, but your tester’s battery is fully charged, you have high resistance.

This usually happens at the junction box. Most trailers have a square plastic box where the main 7-way cable meets the individual wires for the lights. Open it. It’s probably a mess of wire nuts and electrical tape. Use your tester to inject power at the 7-way plug, then use a probe to see where the voltage drops inside that junction box.

Advanced Features to Look For

If you're buying a unit, look for "Short Circuit Protection." This is vital. If you plug a cheap DIY box into a trailer with a direct short, you might melt your tester's internal wiring or pop a fuse immediately. Professional units like the IPA 8000 series have internal circuit breakers that reset automatically. They "pulse" the circuit so you can trace the short with a non-contact tool without burning anything up.

Some modern boxes also include an "ABS" test function for heavy-duty commercial trailers. This allows you to communicate with the trailer's computer to see if there are fault codes stored in the braking system. For the average guy hauling a boat or a horse trailer, that's overkill, but for a fleet mechanic, it's non-negotiable.

Actionable Steps for Your Next Repair

Don't wait until you're stranded on the side of the road to figure this out.

- Clean the Pins: Before you even plug in your trailer light test box, take a bit of sandpaper or a dedicated terminal cleaner to the pins. Oxidation acts like an insulator.

- Check the Ground First: 90% of "weird" behavior—like the tail lights turning off when you hit the brakes—is caused by a bad ground. Ensure the white wire is bolted securely to a clean, unpainted spot on the trailer frame.

- Isolate the Harness: If the tester shows a short, start unplugging individual light fixtures one by one. If the short disappears when you unplug the left rear tail light, you've found your culprit.

- Apply Dielectric Grease: Once you fix the connection, slather it in dielectric grease. It doesn't conduct electricity, but it keeps moisture out, which prevents the corrosion from coming back.

The goal isn't just to get the lights working for today. It's to ensure that when you're hauling a load at 2:00 AM in a rainstorm, you aren't invisible to the guy tailgating you. A reliable tester makes that possible by taking the guesswork out of the most frustrating part of trailer ownership.